Centrifugal Pump Problems Explained

Reduced performance, rising energy costs, overheating, noise, vibration, and flow interruptions can all indicate developing issues.

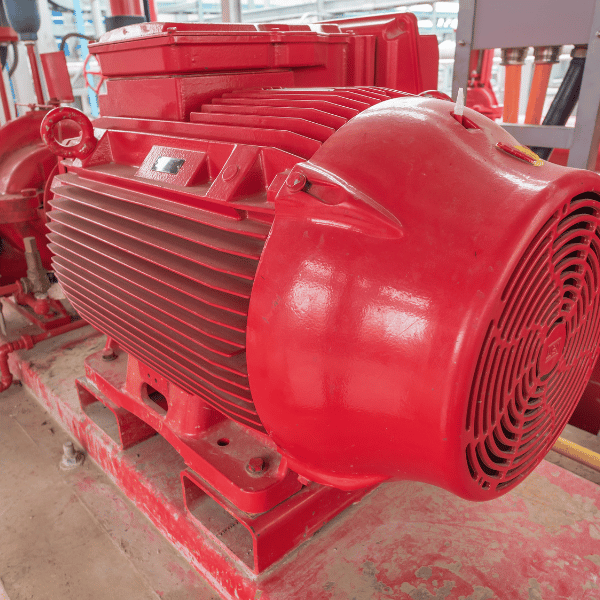

A centrifugal pump plays a vital role in many water, wastewater, irrigation, industrial, and commercial systems. These pumps are relied upon for consistent flow, steady pressure, and dependable daily operation. When a centrifugal pump begins to fail or operate outside its normal range, the entire system can be affected.

Reduced performance, rising energy costs, overheating, noise, vibration, and flow interruptions can all indicate developing issues. As a professional pump service provider, we help property owners, plant managers, contractors, and facility teams diagnose these problems and prevent long-term damage. Understanding the most common centrifugal pump problems can help you recognize early warning signs and know when professional service is needed.

Understanding How a Centrifugal Pump Operates

A centrifugal pump uses a rotating impeller to create flow. When the impeller spins, it pushes water outward, creating a pressure difference that draws water into the pump and forces it through the discharge. This simple but effective design makes centrifugal pumps popular across many industries. Their performance depends on smooth mechanical operation, stable water flow, proper priming, correct alignment, and balanced pressure. When any part of the system is disrupted, the pump may begin to struggle. Recognizing the cause of the disruption is the first step toward restoring normal operation.

Cavitation and Its Impact on Pump Performance

Cavitation occurs when the pressure inside the pump drops low enough for vapor bubbles to form in the water. These bubbles collapse rapidly when they move into higher-pressure areas of the pump. The collapse creates shock waves strong enough to damage impellers, wear down surfaces, and disrupt flow. Cavitation often produces rattling or crackling noises inside the pump. It may also cause vibration or a noticeable drop in performance.

Cavitation occurs when the pump is starved of water, suction conditions are poor, or the pump is operating against excessive resistance. Improper system design, clogged suction lines, undersized pipes, or excessive lift conditions can all contribute to cavitation. As professionals, we inspect the pump, evaluate suction conditions, and determine whether system adjustments or repairs are needed to restore smooth operation. Prompt correction helps prevent long-term damage to the impeller and casing.

Problems Caused by Air Leaks in Suction Lines

A centrifugal pump must remain fully primed to operate properly. Air entering the suction line disrupts the pump's ability to draw water. Small leaks can cause inconsistent flow, pressure fluctuations, or loss of prime, while larger leaks may stop the pump from moving water entirely.

Air leaks often result from loose fittings, failing seals, cracked pipes, or worn gaskets. These issues may not be visible from the surface. Professional testing can pinpoint where air is entering the system. Repairing leaks improves pump performance and reduces strain on the pump. In many cases, correcting a suction leak restores normal flow immediately and prevents unnecessary wear on the impeller and motor.

Issues Related to Clogged or Restricted Impellers

Impellers must rotate freely to generate flow. Sediment, debris, mineral buildup, or corrosion can collect on the impeller blades. Even a small amount of buildup can reduce pumping efficiency. When the impeller becomes clogged, performance drops, energy use rises, and the pump may vibrate.

Some environments are more prone to clogging. Areas with high sediment levels, mineral-heavy water, or industrial contaminants may require more frequent inspection. Impeller cleaning restores performance and extends pump life. If the impeller is damaged rather than clogged, it must be replaced. Professional evaluation helps determine which approach is appropriate.

Mechanical Seal Failure and Leakage

Mechanical seals keep water inside the pump while the shaft rotates. When a seal begins to fail, water may leak from the pump casing. Small leaks may indicate premature seal wear, while significant leaks can cause bearing contamination or motor damage. Seal failure can occur due to heat, misalignment, exposure to chemicals, or normal wear and tear.

Replacing a mechanical seal requires proper tools and experience. Incorrect installation can shorten the seal's life or cause immediate leaks. Professional seal replacement protects the pump and prevents water loss. Seals should also be inspected during routine maintenance to detect early wear before serious problems arise.

Bearing Wear and Overheating

Bearings support the pump shaft and allow it to rotate smoothly. When bearings wear down, the pump may produce grinding noises, heat rapidly, or vibrate during operation. Bearing failure can lead to shaft misalignment or motor strain. It may also cause electrical components to overheat.

Bearings wear for several reasons, including improper lubrication, excessive load, misalignment, or contaminated water entering the bearing chamber. Replacing worn bearings restores smooth rotation and prevents further damage. Professional technicians evaluate the cause of bearing wear so that future failures can be avoided.

Misalignment in Pump and Motor Assembly

Many centrifugal pumps rely on an external motor connected through a coupling. When the pump and motor are not aligned, the coupling experiences an uneven load. Misalignment creates vibration, noise, and accelerated wear on bearings and seals; the pump may struggle to maintain performance, and energy consumption may increase.

Professional alignment using specialized tools ensures that the pump and motor operate as a balanced unit. Proper alignment improves efficiency and extends the lifespan of both components. Alignment should be checked whenever pumps are installed, moved, or serviced.

Overheating and Thermal Stress

Overheating is one of the most common problems in centrifugal pumps. An overheated pump may shut down unexpectedly or produce a burning odor. Overheating can be caused by poor lubrication, restricted flow, bearing failure, improper installation, or electrical issues. Pump motors may also overheat when operating under excessive load.

Professional technicians evaluate all possible causes and test components to identify overheating sources. Correcting thermal stress helps prevent permanent damage to pump windings, bearings, and seals.

Problems Caused by Incorrect Pump Selection

A centrifugal pump must be matched to the system it serves. When a pump is too small, it operates under constant strain, leading to early failure. When a pump is too large, it may cause pressure spikes, cavitation, or energy waste. Incorrect pump selection leads to inconsistent performance and higher operating costs.

Professional assessment during pump replacement ensures that the pump's flow rate, head pressure, and power match the system's needs. This prevents long-term problems and improves overall efficiency.

Influence of Local Conditions on Pump Performance

Local climate, water composition, and environmental conditions all affect centrifugal pump performance. Areas with high sediment levels may require more frequent impeller cleaning. Regions with hard water may experience mineral buildup. Industrial zones may expose pumps to chemicals that reduce seal life. Cold climates may require pumps designed for lower temperatures.

Understanding local factors helps technicians recommend the right materials, protective coatings, and maintenance schedules. This improves pump reliability and reduces the risk of unexpected failures.

Importance of Professional Maintenance

Routine maintenance is essential for centrifugal pumps. Inspections help identify developing issues such as seal wear, bearing problems, air leaks, or impeller damage. Checking electrical components, evaluating system pressure, and cleaning pumps at scheduled intervals help reduce the risk of sudden breakdowns.

Professional maintenance also includes vibration testing, thermal imaging, flow measurement, and pressure monitoring. These tools detect early problems that are difficult to see without specialized equipment. Regular service extends pump life and improves efficiency.

When to Replace a Centrifugal Pump

All pumps eventually reach the end of their performance life. Replacement may be needed when repairs become frequent, energy costs increase, or performance declines even after service. Chronic leaks, repeated bearing failures, or severe corrosion may indicate that replacing the pump is more cost-effective than continued repair.

Professional evaluation helps determine when replacement is the best option. Newer pump designs often offer better efficiency and reduced long-term operating costs, which may justify an upgrade.

Frequently Asked Questions

What causes a centrifugal pump to lose prime?

Air leaks, low water levels, or improper priming are common causes. Professional testing helps identify the source.

Why is my centrifugal pump making loud noises?

Noise may indicate cavitation, bearing wear, impeller damage, or misalignment. Prompt service reduces the risk of long-term damage.

Is cavitation dangerous for a pump?

Yes. Cavitation can erode the impeller and housing. Addressing suction issues prevents further damage.

How often should centrifugal pumps be serviced?

Annual service is recommended for most systems. Pumps used in industrial or high-demand environments may require more frequent maintenance.

Can water quality affect pump performance?

Yes. Sediment, chemicals, and minerals all influence wear and efficiency. Local water conditions should be considered during maintenance.

What are the signs of seal failure?

Leaks, overheating, and moisture near the pump housing may indicate a failing mechanical seal.

Conclusion

Centrifugal pumps are dependable and versatile, but their performance depends on proper care and timely maintenance. Knowing the common issues, such as cavitation, air leaks, impeller blockages, seal wear, bearing fatigue, and misalignment, can help you spot early warning signs before they escalate.Long-term reliability is supported by thoughtful system design, correct installation, and professional upkeep. When issues do occur, prompt attention preserves both efficiency and the pump’s lifespan. With consistent care and the right approach, a centrifugal pump can provide smooth, reliable performance for many years.

Pump Repair Services has over 32 years of experience providing reliable irrigation pump repair and centrifugal pump repair services in the Orlando area. Our extensive industry knowledge and experience allow us to handle any well or pump-related issues efficiently. 24-hour emergency services available. Call us to book a service and get outstanding service and customer experience.